Well-known PCB supplier

Well-known PCB supplier

+8618879561688

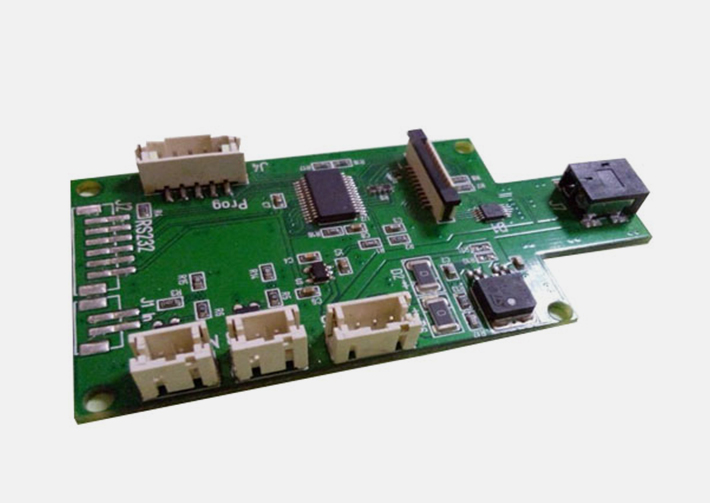

SMT pcb assembly is born with the development of the electronics industry, is with the development of computer application technology, electronics and information technology. SMT pcb assembly can develop at a high speed thanks to its own advantages, the following small Jie brother will introduce some of the advantages of SMT pcb assembly.

1, high assembly density, light weight and small size of electronic products

Chip components than the traditional perforated components quality and area occupied by greatly reduced. Generally, the use of SMT chip technology can reduce the quality of electronic products by 75%, 60% volume reduction.

2、Strong vibration resistance and high reliability

Because the electronic components are short pin or no pin, and firmly mounted on the PCB surface, so the SMT patch strong vibration resistance, high reliability. SMT pcb assembly solder joint defect rate than THT is an order of magnitude lower.

3、Good high frequency characteristics

Because the electronic components reduce the influence of the lead distribution characteristics, and in the PCB surface paste welding firmly, greatly reducing the parasitic inductance and parasitic capacitance between the leads, so to a large extent to reduce the radio frequency interference and electromagnetic interference, improve the high frequency characteristics.

4、Improve production efficiency, easy to realize automation

Compared with THT, SMT is more suitable for automated production. THT requires different smt machines (DIP placement machine, axial placement machine, radial placement machine, taping machine, etc.) according to different components, and each machine needs to be adjusted for assembly time and high maintenance workload. And SMT only use a placement machine, configured with different placement head and shelf, you can install all types of electronic components, reducing the maintenance workload and adjust the preparation time.

5、Cost reduction

SMT pcb assembly so that the PCB wiring density increases, the area becomes smaller, the number of holes to reduce the number of PCB layers with the same function, all of these make the PCB manufacturing costs reduced. Short lead or no lead components save lead material, omitting the bending, cutting line process, reducing the cost of manpower, equipment. The improvement of frequency characteristics reduces RF debugging costs. The reduced size and weight of electronic products reduces the cost of the whole machine. Good reliability of welding, so that the cost of rework reduced. Therefore, the general electronic products using SMT placement technology, can make the total cost of the product to reduce 30%-50%.

With the maturity and development of science and technology, SMT pcb assembly technology will also be more miniaturized, higher speed and more cost effective development.

Connect to a OMNI PCB engineer to support your project!

Request A Quote