High density interconnect PCBs are a way of making more room on your PCB to

make them more efficient and allow for faster transmission. It’s relatively easy for

most enterprising companies that are using printed circuit boards to see how this can

benefit them.

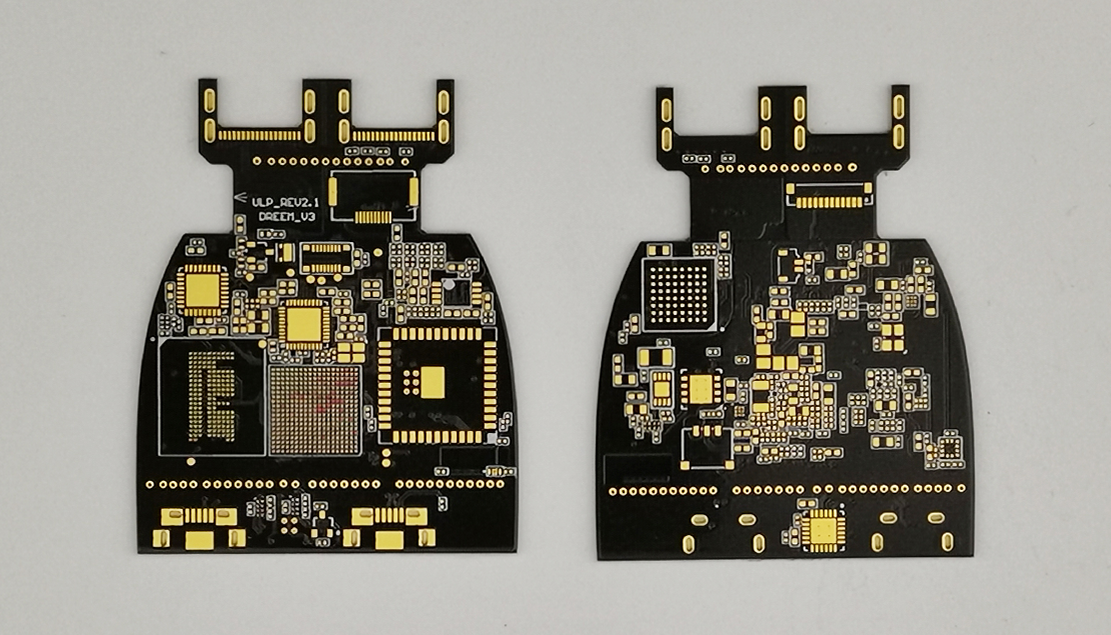

High density interconnect (HDI) PCBs represent one of the fastest-growing segments of

the PCB market. Because of its higher circuitry density, the HDI technology can

incorporate finer lines and spaces, smaller vias and capture pads, and higher connection

pad densities. A high-density PCB features blind and buried vias and often contains

microvias that are .006 in diameter or even less.

Key HDI PCB Benefits

The evolution of PCB HDI technology has given engineers greater design

freedom and flexibility than ever before. Designers using HDI high density interconnect

methods now can place more components on both sides of the raw PCB if desired. In

essence, an HDI PCB gives designers more space to work with, while allowing them to

place smaller components even closer together. This means that a high-density

interconnect PCB ultimately results in faster signal transmission along with enhanced

signal quality.

HDI PCB is widely used to reduce the weight and overall dimensions of products, as well

as to enhance the electrical performance of the device. The high-density PCB is

regularly found in mobile phones, touch-screen devices, laptop computers, digital

cameras and 4G network communications. The HDI PCB is also prominently featured in

medical devices, as well as various electronic aircraft parts and components. The

possibilities for high-density interconnect PCB technology seem almost limitless.

HDI PCB Applications

HDI boards are appropriate for a wide range of industries. As mentioned above, you’ll find them in all types of digital devices, like smartphones and tablets, where miniaturization is key to the effective application of the product. You can also find high-density interconnect PCBs in automobiles, aircraft and other vehicles that rely on electronics.

One of the most critical areas where the high-density PCB is making huge inroads is in the medical arena. Medical devices frequently need small packages with high transmission rates that only HDI PCBs can supply. For example, an implant needs to be small enough to fit in the human body, but any electronics involved in that implant absolutely must efficiently allow for high-speed signal transmission. Here, the HDI PCB indeed is a godsend. HDI PCBs can also be useful in other medical equipment, like emergency room monitors, CT scans and much more.

Well-known PCB supplier

Well-known PCB supplier