Though surface mount technology has become the main mounting method in PCB

manufacturing, there are still some components that are not suitable in SMT assembly.

Then SMT assembly and THT assembly need to be applied on the same board. This

combination of assembly technologies is called a mixed assembly, which does not use

solder paste during the manufacturing process.

Most of the components are welded on the board in surface mount configuration, but for

some certain components that are not available in the SMT process, then mixed PCB

assembly is necessary.

The comparison between SMT assembly and THT assembly

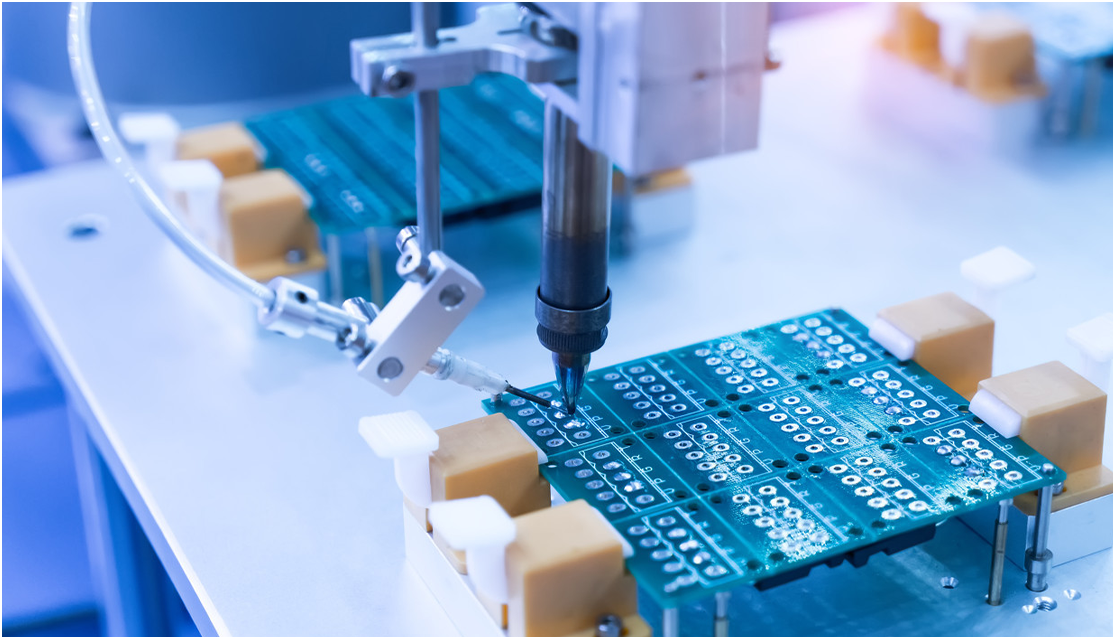

First, SMT components are welded on the board through the reflow machine, and the

process is fully automated. While THT assembly needs pre-drill holes on the board and

using leads to connect the components and circuits, and both wave-soldered and hand

soldered are conventional methods in the THT assembly process.

Secondly, the PCBs with surface mount devices (SMDs) can be reflow or wave soldered, but

the PCBs with through-hole components only can be wave-soldered. Therefore, there are

more steps in the assembly process if both SMT components and THT components are used on

the board. Usually, the SMT process is performed first and then THT assembly.

Thirdly, Advanced and precision machines allow SMT assembly is achieved with high

accuracy and fast speed. Those small-sized and thin components can be placed on the

board precisely, making SMT is more suitable in high-density and small size PCB

applications. And THT is preferred by those components with large size and

high-reliability requirements because it provides more robust connections than SMT

components.

All in all, SMT assemblies feature with high productivity, high precision, lightweight,

and less cost. SMT is more economical and faster for mass production. THT assemblies

usually are highly reliable, high-stress tolerance, heavier, and more expensive. THT is

the preferred assembly method for small quantity PCBs and prototyping fabrication.

The applications of mixed assembly

Mixed assembly is usually used in applications that require a combination of through-hole components and SMT components. You can find mixed technology in the following applications:

CPUs

Smartphone accessories

Communication hardware

Server boards

LED lighting products

Video processing

Industrial controller assemblies

Well-known PCB supplier

Well-known PCB supplier