Well-known PCB supplier

Well-known PCB supplier

+8618879561688

We can see a lot of various production equipment in the SMD factory, one of the equipment generally does not attract much attention, that is the first sample of inspection instrument. Generally in SMT chip processing, quality and delivery is the most concerned about the majority of customers, in order to protect the quality of SMT chip batch, professional SMT chip processing plant will be the first piece of testing, the purpose is to find the factors affecting product quality in the production process as early as possible, to prevent batch of bad or scrap.

The purpose of the first sample inspection.

1, the production process of the first sample of inspection is mainly to prevent the product from appearing in batches of super poor, rework, scrap, it is a means of pre-emptive control of product production over, is an important method of product process quality control, is a proven and effective way to ensure product quality, improve economic efficiency, essential methods.

2, the first sample is to find out the factors affecting product quality in the production process as early as possible, to prevent the batch of bad or scrap.

3, the first sample of inspection before entering the formal production, mainly to prevent the occurrence of batch of non-conforming products.

4, long-term practical experience has proved that the first inspection system is an early detection of problems, to prevent the product batch scrap of effective measures. Through the first inspection, can find such as jigs and fixtures serious wear or installation positioning error, measuring instrument accuracy deterioration, reading the wrong drawings, feeding or formulation errors and other systemic reasons exist, so as to take corrective or improvement measures to prevent the occurrence of batch non-conforming products.

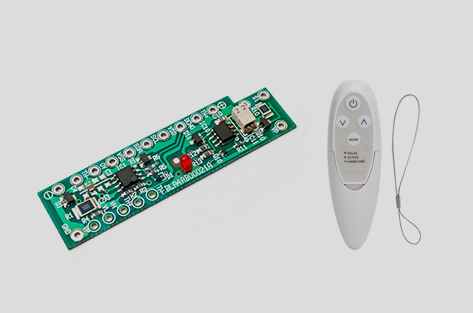

SMT placement of the first product in the production process needs to go through the online SPI, online AOI, X-RAY, QA, QC and other layers of inspection, online SPI inspection is to detect the first product solder paste printing effect; online AOI inspection is the test of the solder joint and the database of qualified parameters for comparison, after image processing, check the PCB on the defect, and through the display or automatic sign The defects are displayed / marked out; X-ray through the high penetrating ability of X-ray, detection and analysis of internal displacement of components whether changes; QC inspection when the SMT placement process are completed, QC needs to be inspected to confirm whether there is leakage paste, reverse wrong parts and other issues, adhere to the 9 inspection process layer by layer, only to better protect product quality.

5.PCBA processing inspection requirements.

Combined with Omni PCBA processing inspection we generally use the first three inspection system is also self-inspection, mutual inspection and special inspection.

6, the first sample of testing standards should be the first piece of standards or process guidance documents, to this standard to require production to protect and improve the quality of PCBA processing.

Second, the benefits of PCBA processing first piece testing.

1, PCBA manufacturing first piece testing can avoid poor quality products in batches, rework, scrap, etc., can ensure product quality and improve economic efficiency.

2, can be found in advance in PCBA processing factors affecting product quality, can prevent batch of bad or scrap.

3、It can reduce the risk of wrong parts, reduce the chance of error, and effectively improve the production quality.

Connect to a OMNI PCB engineer to support your project!

Request A Quote