Well-known PCB supplier

Well-known PCB supplier

+8618879561688

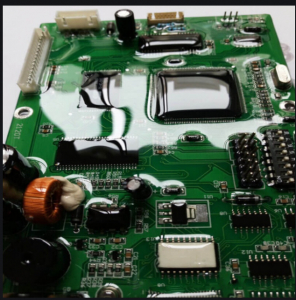

conformal coating painting is a specially formulated coating used to protect circuit boards and their related equipment from environmental erosion. The conformal coating has good resistance to high and low temperatures; its curing into a transparent protective film, with superior insulation, moisture-proof, anti-leakage, shock-proof, dust-proof, anti-corrosion, anti-aging, corona resistance and other properties.

How to paint the conformal coating on the pcb ?

PCBA board can not paint some of area

1. Some of need electrical connection area: such as gold pads, gold fingers, metal through holes, test holes, etc;

2. battery and battery holder;

3. connectors;

4. fuses and housings;

5. heat dissipation devices;

6. jumper;

7. optical device lens;

8. Potentiometer;

9. sensors;

10. switches that are not sealed;

11. other areas that will be affected by the coating performance or operation: for example, inductive components, the coating of the three-proof paint is likely to affect the electrical properties, must be tested in advance.

PCBA board must be coating areas

In addition to the above mentioned areas, all other solder joints, component tube legs, component conductor parts should be coated, generally for the components that must be masked for protection treatment after the PCBA whole board for coating.

conformal coating technology requirements and technology specifications

Painting requirements.

1, Thickness: paint film thickness control in 0.05mm-0.15mm. dry film thickness 25um-40um.

2、Secondary coating: To ensure the thickness of products with high protection requirements, can be done after the paint film is cured

3, check and repair: visual inspection of the coated circuit board to check whether the quality requirements, and to repair the problem. Such as: pins and other protected areas stained with three anti-varnish, available tweezers clip degreasing cotton balls or clean cotton balls dipped in board washing water will be scrubbed clean, scrubbing attention should not be normal paint film washed off.

4、Component replacement: After the curing of the paint film, if you want to replace the component ware, you can operate as follows.

(1) direct soldering of components with electric chromium iron, and then clean the material around the pad with a cotton cloth dipped in washboard water

(2) welding replacement components

(3) solid with a brush dipped in three-proof paint brushing welding parts, and make the paint film surface dry curing

PCBA board must be coated with three anti-varnish areas

In addition to the above mentioned areas, all other solder joints, component tube legs, component conductor parts should be coated, generally for the components that must be masked for protection treatment after the PCBA whole board for coating.

Benefits of conformal coating:

Insulation, allowing reduction in conductor spacing Reduce the need for complex, sophisticated enclosures

Minimal effect on component weight

Protection against chemical and corrosive attack

Improve performance and reliability of products subject to environmental conditions

Provide mechanical support and vibration resistance

Enhanced product reliability

Applying a conformal coating

Essentially there are 3 main ways to apply a conformal coating to protect your boards.

Dipping

Usually the highest volume technique. Boards are dipped in the conformal coating and coating penetrates everywhere. Masking in this application must be perfect to prevent leaking. Due to design, many PCB boards are unsuitable for this method, but if designed with conformal coating in mind then the ‘dipping’ process can be used in high volume manufacturing.

Brushing

Suitable for low volume manufacture, finishing and repairing units. Requires highly skilled operatives to get a suitable protection level.

Spraying

Coatings are applied with a spray aerosol or dedicated spray booth using a spry gun and is the most suitable method for low to medium volume manufacture. Most coatings can be applied this way.

After boards are conformal coated they will then need curing either by air dry, oven dry or UV light cure. Once the process of coating has been completed the coating is clearly visible as a clear and shiny material, some are hard while others have a slightly rubbery texture.

The team at 4e have been applying conformal coatings for nearly 20 years in military, medical and aerospace products. Meanwhile, Stock Electronics, which has produced motor control products for outdoor and harsh environments for 30 years, continues to use a range of conformal coatings across its product portfolio.

Connect to a OMNI PCB engineer to support your project!

Request A Quote